Thank you so much for the measurement photo!

-

For more information on how to avoid pop-up ads and still support SkiTalk click HERE.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Volkl Piston Race Plate Question

- Thread starter cruxkill0

- Start date

I picked up my skis today. Thanks to the help from this site, I confirmed everything looks perfect with toe and placement, boot center. I do have the following questions to run by the community here.

My DIN is 8, I know this is correct. The toe is set to 8. The heel is set to 7. I asked why? The shop explained that when they test the release in the machine, that is how they determine the exact setting of the release force, rather than just relying on the number scale on the binding. Does this make sense to everyone here?

The forward tension screw is not screwed in flush with the housing of the binding. The boot is locked in solid. No wiggle in the toe. The tension feels correct, the force I need to lock in my boot feels normal and correct. I am thinking the flush with housing "rule" does not apply to these bindings?

Last the anti friction plate on the toe just barely makes contact with the bottom of the boot, but I read there should be 1/2 a MM of space, enough to slide a business card between boot bottom and anti friction plate. Again not sure if this "rule" applies to these bindings and boots?

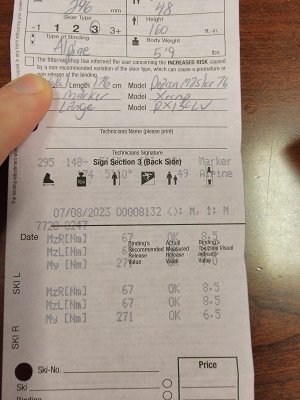

I received a copy of the bindings release test.

My DIN is 8, I know this is correct. The toe is set to 8. The heel is set to 7. I asked why? The shop explained that when they test the release in the machine, that is how they determine the exact setting of the release force, rather than just relying on the number scale on the binding. Does this make sense to everyone here?

The forward tension screw is not screwed in flush with the housing of the binding. The boot is locked in solid. No wiggle in the toe. The tension feels correct, the force I need to lock in my boot feels normal and correct. I am thinking the flush with housing "rule" does not apply to these bindings?

Last the anti friction plate on the toe just barely makes contact with the bottom of the boot, but I read there should be 1/2 a MM of space, enough to slide a business card between boot bottom and anti friction plate. Again not sure if this "rule" applies to these bindings and boots?

I received a copy of the bindings release test.

YesI picked up my skis today. Thanks to the help from this site, I confirmed everything looks perfect with toe and placement, boot center. I do have the following questions to run by the community here.

My DIN is 8, I know this is correct. The toe is set to 8. The heel is set to 7. I asked why? The shop explained that when they test the release in the machine, that is how they determine the exact setting of the release force, rather than just relying on the number scale on the binding. Does this make sense to everyone here?

Is the screw sticking out, or recessed a bit into the heel? Is the screw sitting in the same position of both heels?The forward tension screw is not screwed in flush with the housing of the binding. The boot is locked in solid. No wiggle in the toe. The tension feels correct, the force I need to lock in my boot feels normal and correct. I am thinking the flush with housing "rule" does not apply to these bindings?

The XComp toes do not have any adjustment for this and don't need it. The entire AFD is on a track and will move with the boot during release.Last the anti friction plate on the toe just barely makes contact with the bottom of the boot, but I read there should be 1/2 a MM of space, enough to slide a business card between boot bottom and anti friction plate. Again not sure if this "rule" applies to these bindings and boots?

I received a copy of the bindings release test.

Thanks for clearing up my questions. Only remaining possible issue is forward tension screw. It is sticking out a bit, equal on both bindings. I have attached a photo of each binding. Again, the tension feels correct, the force to lock in the boot. No wiggle in toe. If these where in flush, I doubt I could even get the boot in.

Attachments

Slightly too much forward pressure is better than not enough, so an extra click in is still good.Never mind about the forward pressure. I am an idiot. With the boot lock in, the screw is 99 percent flush.

I was thinking the same. Adjust the forward pressure with the boot locked in? To the right, clockwise?

Yes, an extra clockwise click or two(1/4 to 1/2 turn)to make it actually flush(hair out still) and then most do another click or two past that so it’s SLIGHTLY inside the outer housing.I was thinking the same. Adjust the forward pressure with the boot locked in? To the right, clockwise?

Flush

2 extra clicks in

Last edited:

Best practice is to adjust the screw without the boot in there. Then click the boot in and check the location of the screw.I was thinking the same. Adjust the forward pressure with the boot locked in? To the right, clockwise?

Ok 2 more clicks made the screw flush. Then I went 1 more click to slightly inside the housing. I call it perfect by my eye. Clicked boot in and out several times, screw did not move. I am ready to go, thank you everyone! This has amazing members!

Attachments

Yes - My ski tech set up my bindings like this after I was having pre release issues. Takes the slop out of using the approved range and sets the bindings on point. Immediately took all my skis to the shop to be set up the same way and have had no problems since. This is the correct way to set a binding in my world. The majority of the ski world follows the standard procedure.My DIN is 8, I know this is correct. The toe is set to 8. The heel is set to 7. I asked why? The shop explained that when they test the release in the machine, that is how they determine the exact setting of the release force, rather than just relying on the number scale on the binding. Does this make sense to everyone here?

This is my bindings test report. In the interest of learning, if someone could confirm? I believe it means both bindings are set to release at 271 nm of force. The corresponding visual indicates are set to achieve that? This works out to a general DIN of 8, but the actual release is specifically for me based on the machine, DIN 8 is a general range.

Attachments

YesThis is my bindings test report. In the interest of learning, if someone could confirm? I believe it means both bindings are set to release at 271 nm of force. The corresponding visual indicates are set to achieve that?

The DIN indicators on bindings are not precision instruments. There is manufacturing variability within the binding as well as variability with the boot/binding interface. The binding test machine takes all of that variability out of the equation to get you to a true DIN of 8.This works out to a general DIN of 8, but the actual release is specifically for me based on the machine, DIN 8 is a general range.

Sponsor

Staff online

-

Jim KenneyTravel Correspondent

Members online

- zircon

- Vernasem

- Deke

- Novaloafah

- PlainsSkier

- Nancy Hummel

- Norther1

- Gina D

- Brian Finch

- NAC

- Jim Kenney

- DebbieSue

- dan ross

- socalgal

- BLiP

- saboteur

- precisionchiro

- Spoorosew

- Andreasfic

- ss20

- S.H.

- Yepow

- MalcolmOrads

- AltaSkier

- MOMENTinTime

- Cheizz

- Matt Merritt

- Zongyu

- mcmary

- Evagju

- sparty

- peterm

- Evawft

- Dean

- LiquidFeet

- butleri

- Chris V.

- Bruno Schull

- graham418

- skiki

- Even_Stevens

- Gary Stolt

- BMC

- davjr96

- skipress

- Spinning Wheel

- JohnL

- JoeSchmoe

- jdwalk

- GB_Ski

Total: 3,063 (members: 161, guests: 2,098,robots: 804)