This is pointless. Removing wax with base cleaner might be appropriate if the wax is dirty or you're trying to de-fluoro the base, but if not just scrape it off, brush a little, and wax over it. It's fine to have old, good wax under newer wax.Decided that I will use base cleaner to remove factory wax, instead of hotwaxing.

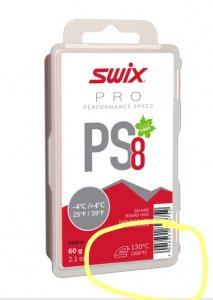

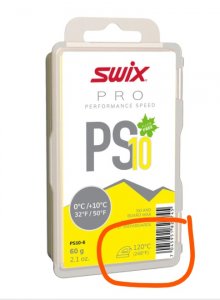

While burning/melting bases is an issue, I worry you don't know what you are doing in terms of temperatures. Unless you stick only to the softest waxes, you are certainly going to be waxing over 100C.

That heat is necessary to melt the wax, and as long as that energy is going into transforming solid wax to liquid, your skis will be OK.

The iron should be HOT - so hot the wax readily melts (but doesn't smoke) - and moving on a layer of wax, so it does not actually touch the base. You should see 2-5 inches of molten wax behind the iron as you move it. Keep the iron moving (one direction is best - people who move the iron back and forth sometimes can get distracted and leave the iron in one place). Do not reheat liquid wax - as long as its liquid its being absorbed, so you can wait a few seconds or even half a minute before another pass with the iron. With nordic skis 2 to 4 passes is enough for a layer of wax, and I suspect that is true for alpine skis.

I've seen beginner try to keep the iron pretty cool to protect their bases, but that's dangerous - it results in them moving the iron slowly and the wax going on bumpy, which increases the risk of burning the base. Have the iron hot so the wax turns to liquid fast, and move quickly.

With new nordic skis that had not been hotboxed, I'd do many layers before skiing on them. At least four to six: two or three very soft, maybe a couple medium, and a couple hard. Then wax of the day.

I urge you to watch some videos on hotwaxing, such as from Swix. This is nordic, but note how fast the wax liquifies and speed which this guy moves. That will protect your bases.

Last edited: